Uses and characteristics

Using Carbide Rotary Burrs is a effective way to realize mechanization in hand workoperations.In the industries of airplane,ship building,automoble,machinery,chemistry etc.Carbide Rotary Burrs can be widely used in machining iron,steel casting,carbon steel,alloy steel,stainless steel,hardened steel,copper aluminium etc.

● Machining various kinds of metal material including ≤HRC65 hardened steel.

● Instead of small emery wheels,without powder pollution.

● Increasing productivity of several ten times than using hand tools and three to five times than using small emery wheels

● Having long life of ten times than high speed steel burrs and fivty times than small emery wheels.

● Finish m achining various kinds of die cavities.

● Removing the burrs of the castings,forgings and the welding spatter on the weld assemblies.

● Chamfering angle,circular bead or flute on the mechanical components.

● Chamfering or burring the pipes.

● Polishing the impeller channel.

● Grinding the hole to an accurate shape.

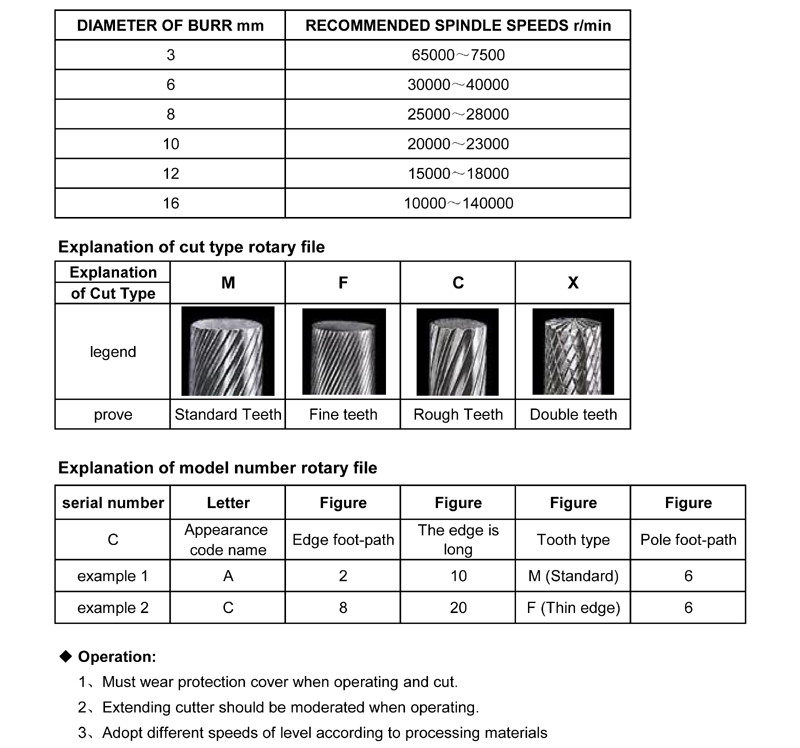

The machines which are used for Carbide Rotary Burrs are usually hand-held,powered either by compressed air or electricity.Be careful about mounting and handling the burr correctly. Only ar high speed,can carbide rotary burrs show their remarable performance.Recommended spindle speeds.

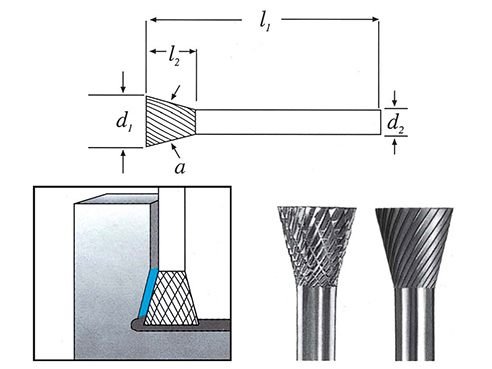

| Inverded Cone (shape N) |

| Item No. |

Cut dia |

Cut length |

Shank dia |

Total length |

a |

| N0304M06 |

3 |

4 |

6 |

55 |

10° |

| N0607M06 |

6 |

7 |

6 |

65 |

10° |

| N0810M06 |

8 |

10 |

6 |

65 |

10° |

| N1010M06 |

10 |

10 |

6 |

65 |

20° |

| N1213M06 |

12 |

13 |

6 |

65 |

20° |

| N1616M06 |

16 |

16 |

6 |

65 |

20° |